A good product is not enough to make a company leader in the market. Maintenance and performance have always to be on top. Let’s see how the most innovative industries are moving in this field towards the greatest business results.

The main companies’ problems are:

- Difficulties in internal data management, which are in a constant state of flux;

- Inability to obtain valuable insights from devices.

It is complicated but also very important to get a sense to all this information, especially because lots of people have to be able to read and to interpret them quickly, to make decisions and solve problems.

Most of companies, including ours, decided to adopt an IoT solution to analyse data both from inside and outside the office, to send real-time workable insights to all the people who need them to monitor the processes’ behaviours and to improve performances in order to reach great business results.

IT teams, both developers and operations, will be able to develop IoT solutions. This system will help to:

- Connect

- Manage

- Provision

billions of IoT devices in a simple and safe way. We are talking about a real “bridge” between company’s devices and cloud solutions.

Advanced analytics help to optimize costs, predict all the maintenance needs and remove all stops and delays occurring during processes (a product delivery, for instance, or a component creation, especially concerning factories), which can cause a lot of extraordinary costs and customers’ dissatisfaction.

Microsoft IoT Hub

One of the best IoT development and management enabler is Microsoft Azure IoT Hub, inside which the Italian company Solair (acquired by Microsoft in 2016) has been integrated.

After connecting the devices to IoT Azure, the suite enables the orchestration between code and services to distribute the artificial intelligence over all devices. It optimizes the development IoT efforts using the existent resources’ competencies, frequently used tools and different languages to improve and monitor your solution. Through the Artificial Intelligence and the advanced analysis, you can reduce your IoT solution costs and you can also use your devices offline or with intermittent connection.

Microsoft IoT Hub allows to easily and safely connect all your IoT Microsoft Azure devices. It is possible to:

- establish a two-way communication between all the IoT devices

- use familiar platforms and protocols

- make reliable updates

- manage all devices in a scalable way with new peripheral equipment management functionalities

IoT Hub actions are based on peripherals to ensure the privacy of messages between the cloud-to-device and device-to-cloud.

IoT Microsoft Azure main feature is its capability to integrate existent devices with IoT solutions, which are completely customizable.

Let’s see two examples:

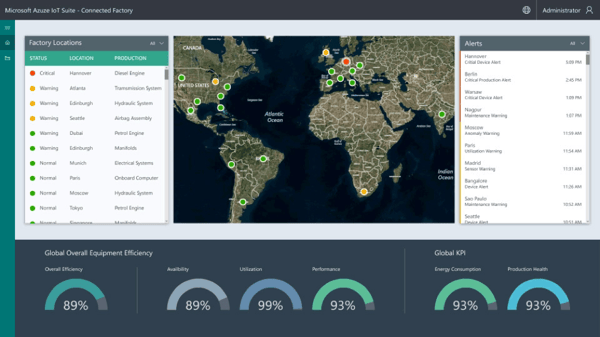

In case of manufacturing companies working in industrial environment:

- The global dashboard gives an overall picture of their worldwide business.

- At a glance, you can easily see their structures, performances, efficiency and product status in the critical report.

- Alarms, interruptions and anomalies are in order of importance inside the alert log to be able to solve them faster.

- There is the possibility to use different display typologies: (A) global for the whole company, (B) focused on the production line or on machines, (C) for systems resolution.

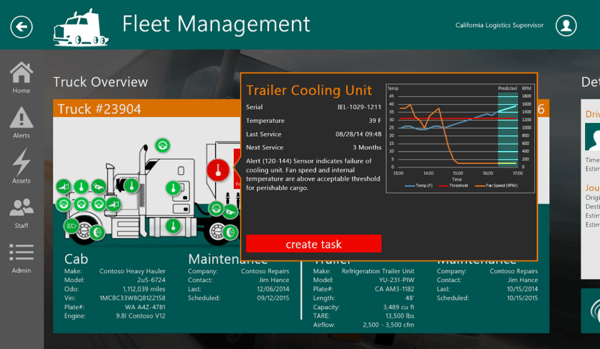

In case of companies working in the transport sector:

- Alarms and anomalies are immediately identified and ordered to highlight the critical points, allowing the user to act immediately.

- Notifications can be activated depending on the specific company’s needs or by setting thresholds directly inside the dashboard.

The importance of notifications

Thanks to this kind of software, each person belonging to a specific team can immediately and proactively act in the right place at the right time, reducing costs and optimizing the processes.

Which companies chose it

There are lots of companies all over the world that chose to use it, belonging to all sectors: banking, industry, construction and software. One of the main representative case study is the Rolls-Royce one, with its predictive data analysis that helps more than 13.000 planes to optimize their engine performances by choosing the best fuel level to increase the efficiency, reduce consumption, save millions of dollars every year and improve the customer experience.